Info, Knowledge Base

How to Maintain your Scroll Pump – Tip Seal Change

It is important that you carry out a tip seal change on your scroll pump at least once a year to keep your pump working efficiently and remove any residue which may hinder performance.

Every year when its time to perform a tip seal swap, we recommend that you follow the steps in this video. It is also advised to carry out a tip seal change if the vacuum is not achieving its desired pressure or if there are any out of the ordinary noises coming from the pump.

Tools You Will Need

Before you begin, make sure that you are equipt with the tools you will need:

- Allen Key (4mm)

- Lint free towels

- Philips head screw driver

- Flat head screw driver

- Green scourer

- Rubbing alcohol

- Cotton swabs

- Adjustable spanner (set to 30mm)

- Stanley Knife

Tip Seal Change Preparation

- Unscrew the 4 screws in front of the pump using the allen key

- Remove the exhause port on the side of the pump with an adjustable spanner set to 3mm

- Firstly, unscrew the gas ballast off

- Pull the front of the pump off

- Carefully lay the pump on its back

- Remove the electrical connector to the fan using your flat head screw driver

- Notice there are 4 screws along the edge which you will unscrew using your allen key – do not remove the fan screws

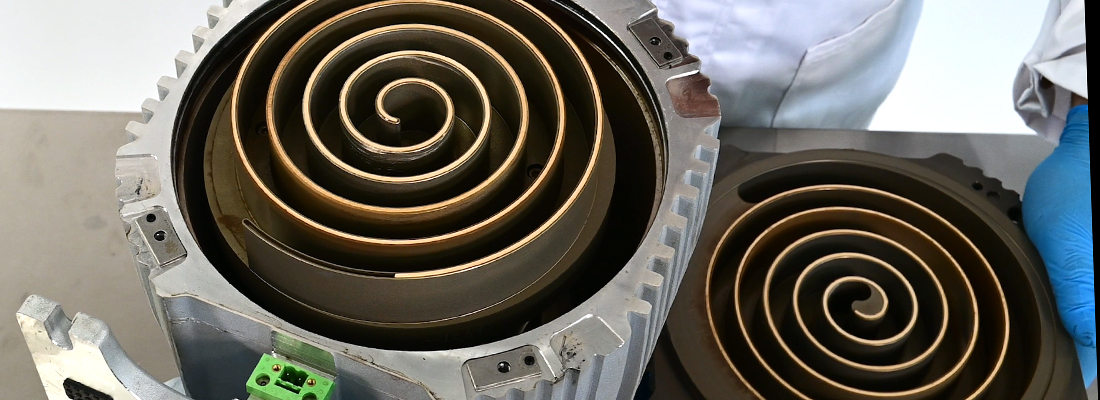

- Pull off the top to reveal the scrolls

- Remove the old tip seal by pealing it off and remove the O-ring around edges

Cleaning the scrolls

- Using rubbing alcohol, gently clean the scrolls using your lint free towel and swabs

- Any resedue detected will need to be scrubbed off using your green scourer and soapy water.

Install The New Tip Seal

- Carefully feed the new tip seal into the scrolls, you will notice that on the scrolls there are some teeth which are designed to bite onto the tip to make sure that it doen’st escape or slide around whilst feeding it back in

- When you get to the end of the scroll there will be a 2cm gap indicator which is where you will need to slice the end off of the tip

- Repeat this process with the other half of the scroll

- Carefully reassemble your scroll pump reversing the previously mentioned steps

Following your tip seal swap, your scroll pump will obtain its best vacuum performance after running it for 3-4 hours on an empty chamber, this will let it settle. Once it has settled, you may commence freeze drying.