Info, Knowledge Base

The Science of Freeze Drying: How it Works and Why it’s Useful

Freeze drying, also known as lyophilization, is a complex process used to preserve biological materials such as food and pharmaceuticals by removing water from them. This process has found many applications in various fields, such as food science, pharmaceuticals, biotechnology, and space exploration. In this article, we will explore the freeze-drying process, the benefits it offers, and its applications.

The Freeze Drying Process

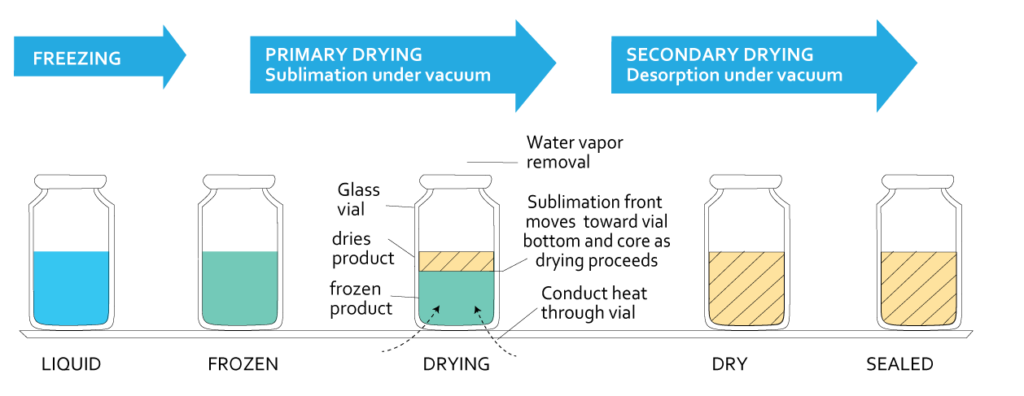

Freeze drying is a three-stage operation consisting of freezing, primary drying, and secondary drying. The first stage involves freezing the material to form a solid structure of ice crystals. The material is then subjected to reduced pressure and a controlled temperature, allowing the ice to sublimate from a solid state to a gaseous state. This is the primary drying stage.

The final stage is secondary drying, where any remaining water molecules are removed by raising the temperature of the chamber. This is done by desorption, where the water molecules are evaporated from the surface of the material. This process can take several hours or even days, depending on the material being dried.

The Benefits of Freeze Drying

One of the main benefits of freeze drying is that it allows for long-term preservation of biological materials without the need for refrigeration. By removing water, which is necessary for bacterial growth, freeze-dried products have an extended shelf life. Freeze drying also preserves the flavour and nutritional content of food products better than other preservation methods, such as canning or dehydration, because it does not use high temperatures that can damage or denature the food’s natural components.

Another advantage of freeze drying is that it can preserve the structure of the material being dried. This is particularly important for pharmaceuticals and biotechnology applications, where the structure of the material can affect its efficacy. Freeze drying also reduces the weight and volume of the material, making it easier to transport and store.

Applications of Freeze Drying

Freeze drying has found many applications in various fields, including food science, pharmaceuticals, biotechnology, and space exploration. In the food industry, freeze-dried products include fruits, vegetables, meats, and instant coffee. These products are popular with hikers and campers, as they are lightweight, easy to transport, and have an extended shelf life.

In the pharmaceutical industry, freeze drying is used to preserve drugs and vaccines. By removing water, the drugs and vaccines can be stored at room temperature without the risk of degradation. Freeze drying is also used to stabilize enzymes, proteins, and other biological molecules.

In the pharmaceutical industry, freeze drying is used to preserve drugs and vaccines. By removing water, the drugs and vaccines can be stored at room temperature without the risk of degradation. Freeze drying is also used to stabilize enzymes, proteins, and other biological molecules.

In the biotechnology industry, freeze drying is used to preserve cells and tissues for research purposes. Freeze-dried cells and tissues can be stored for extended periods and used for experiments when needed. Freeze drying is also used to produce diagnostic kits and reagents.

Finally, freeze drying has applications in space exploration. Freeze-dried foods are used on space missions because they are lightweight and have an extended shelf life. Freeze drying is also used to preserve biological samples collected during space missions.

Conclusion

Freeze drying is a complex process used to preserve biological materials by removing water from them. The process involves freezing, sublimation, and desorption to produce a dry, stable product with an extended shelf life. Freeze drying offers many benefits, including preservation of flavour and nutritional content, preservation of structure, reduction of weight and volume, and long-term storage at room temperature. Freeze drying has found many applications in various fields, including food science, pharmaceuticals, biotechnology, and space exploration.