Info, Knowledge Base

Exploring the History and Evolution of Freeze-Drying Technology

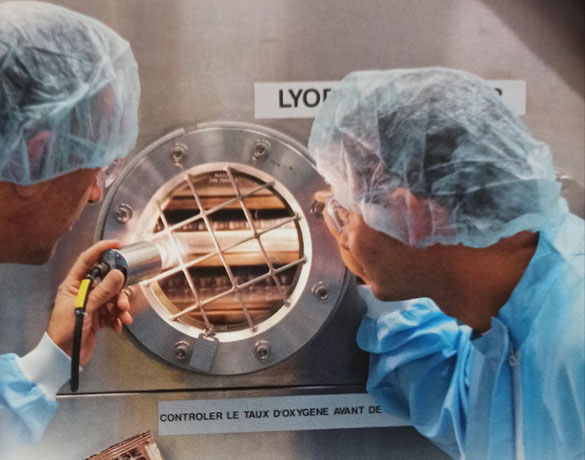

Freeze drying, also known as lyophilization, is a preservation method that has been in use for over a century. It is a process of removing water from products by subjecting them to low pressure and temperature, which allows the water to sublimate without passing through a liquid phase. This technique has revolutionized the preservation industry, allowing foods, medicines, and other materials to be stored for extended periods without spoilage. In this article, we will explore the history and evolution of freeze-drying technology.

Early Beginnings

The earliest form of freeze drying can be traced back to the ancient Incas, who used the technique to preserve potatoes for long-term storage. They would first freeze the potatoes in the high-altitude Andes, and then place them in the sun to allow the ice to evaporate. In the 17th century, European scientists experimented with freeze drying, using it to preserve blood samples and other biological specimens.

The Modern Era of Freeze Drying

In the early 20th century, freeze drying technology began to advance rapidly. In 1906, Jacques-Arsène d’Arsonval, a French physicist, developed the first modern freeze dryer. He used a vacuum pump to remove air from a chamber and then cooled it to freeze the products inside. The ice was then sublimed by applying heat to the chamber. The process was time-consuming and not very efficient, but it was a significant step forward in the development of freeze-drying technology.

In the 1930s, the first commercial freeze dryer was developed by the pharmaceutical company S.M. Jones. The company used the technology to produce penicillin, which was a game-changer in the medical industry. The freeze-dried penicillin was easier to store and transport than its liquid form, and it had a longer shelf life.

Advancements in Freeze Drying Technology

Over the years, freeze drying technology has continued to evolve. In the 1940s and 1950s, researchers developed more efficient vacuum pumps, which allowed for faster freeze drying times. In the 1960s, freeze dryers became automated, which allowed for more precise control over the process. In the 1970s, freeze drying was used to preserve a wide range of products, from fruits and vegetables to meats and dairy products.

In the 1990s, freeze drying technology was further advanced with the development of new materials, such as glass-like polymers and synthetic membranes, which helped to improve the stability and shelf life of freeze-dried products. Today, freeze drying technology is widely used in many industries, including food production, pharmaceuticals, and biotechnology.

Conclusion

Freeze drying technology has come a long way since its early beginnings in ancient Peru. Today, it is a highly advanced process that allows for the preservation of a wide range of products. From penicillin to astronaut food, freeze drying has played a significant role in the advancement of science and technology. As research continues, it’s likely that we will see even more advancements in freeze drying technology in the future.

One such design is the CryoDry® CD8 freeze dryer, which is specifically targeted to replace manifold freeze dryers. This new design allows for a one-step-process that gives the operator total control over the process.

In conclusion, freeze drying technology has come a long way since its early beginnings, and the CryoDry® CD8 freeze dryer is just one example of how technology is advancing to meet the needs of various industries. With its advanced features and efficient design, this new freeze dryer is set to make a significant impact on the food & beverage, environmental, education, biotechnology industries and beyond.

Contact us here at CryoDry® to get more information as to how you can benefit from the CryoDry® range of freeze dryers.